Your Pioneer in Circular Solvents

Solvent recycling, recovery of biotech solvents and specialty chemicals, mainly used in the chemical, pharmaceutical and paint industries are our specialty.

Our Services

Batch

Distillation

Flexible and cost-effective distillation method for smaller volumes, typical campaign size from 3m³ to 250 m³.

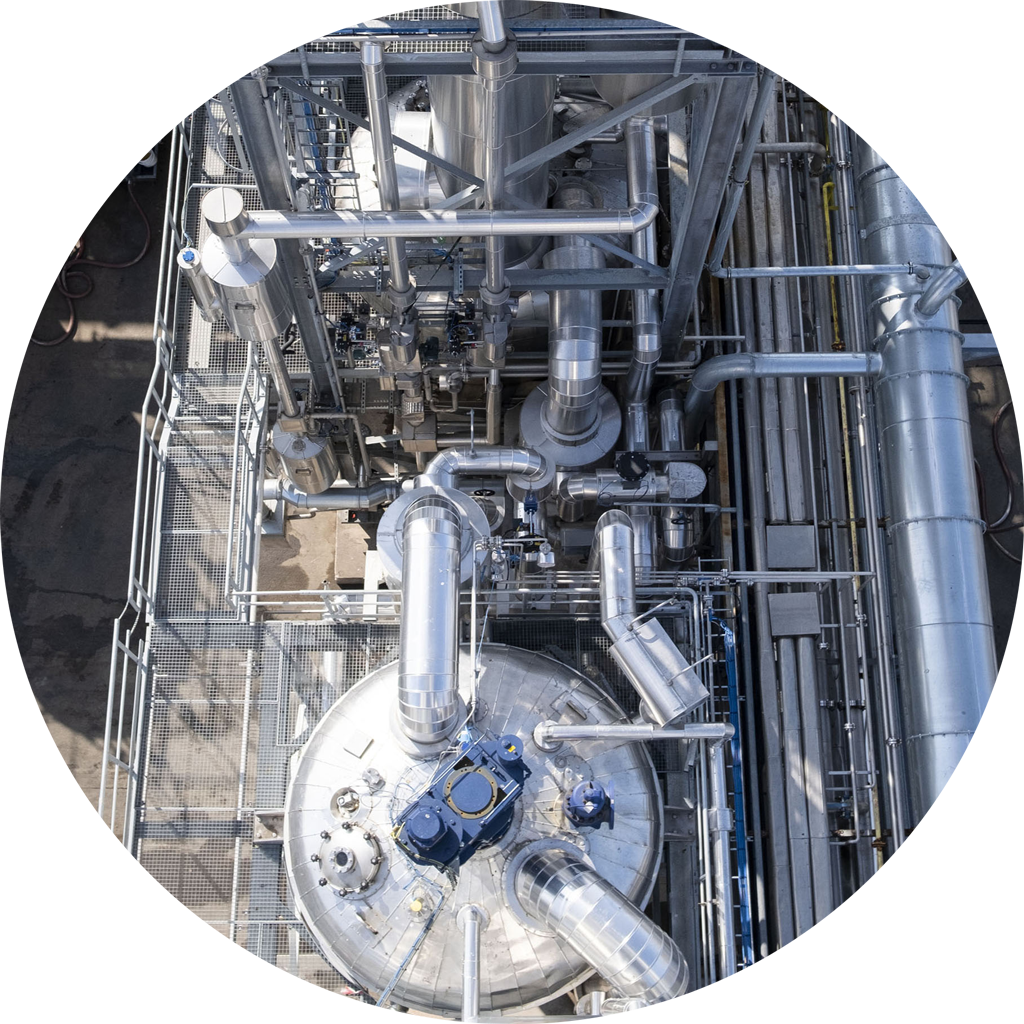

Continuous

Distillation

Larger campaign sizes between 50-1000 m³ are treated in a continuous way. The residence time inside the installation is also reduced; hence thermal stress on the molecule is lower.

Pressure Swing

Distillation

Extractive

Distillation

Short Path

Distillation

An evaporation technique with minimal travelling distance between evaporator and condenser. This allows very low vacuum, up to 0,02 mbar, creating minimal thermal stress.

‘It’s a waste to

waste your waste’

This has been the motto of DNCP for over 40 years and in today’s environment it is even more valid. De Neef Chemical Processing has great expertise in recovering and purifying valuable waste solvent or by-product streams, whether you wish to recover the used solvents yourself or have us develop downstream uses for you.

‘Excellence in

solvent purification’

Since 1980, innovation has been key in our work. With our recognized R&D centre led by top chemists and engineers, we are able to offer innovative and professional solutions for our clients, to be their partner in solvents in a circular economy. We aim to contribute to the world’s most compelling challenges of our time, taking care of our environment by providing sustainable solutions.

‘Close the loop‘

DNCP offers toll distillation to its partners to contribute to a more sustainable world. Every company should be aware that it is possible to recycle their solvent waste streams, and can be re-introduced again in their production process. It is the belief of DNCP that to reach full the product life cycle sustainability, this cycle needs to be closed. Products need to be used for the same purpose or need to meet or exceed original specification in order to truly be sustainable.